Things about Roar Solutions

Things about Roar Solutions

Blog Article

The Roar Solutions Diaries

Table of ContentsThe Greatest Guide To Roar SolutionsNot known Facts About Roar SolutionsRoar Solutions for BeginnersNot known Facts About Roar Solutions

The equipment register is a comprehensive data source of equipment documents that includes a minimum set of fields to determine each product's area, technological parameters, Ex-spouse category, age, and environmental data. This details is vital for tracking and managing the devices effectively within unsafe areas. On the other hand, for periodic or RBI tasting evaluations, the quality will be a combination of In-depth and Close inspections. The proportion of Thorough to Shut inspections will be established by the Equipment Threat, which is examined based on ignition risk (the likelihood of a resource of ignition versus the chance of a flammable atmosphere )and the dangerous location category( Zone 0, 1, or 2). This variation will certainly also affect the resourcing needs for work prep work. As soon as Lots are defined, you can develop sampling plans based on the sample size of each Lot, which refers to the number of arbitrary tools products to be evaluated. To establish the called for sample size, two aspects require to be evaluated: the size of the Lot and the group of examination, which shows the level of effort that must be applied( decreased, regular, or increased )to the inspection of the Lot. By incorporating the category of inspection with the Great deal size, you can then develop the ideal rejection standards for a sample, indicating the allowable number of defective products discovered within that sample. For more information on this process, please refer to the Energy Institute Standards. The IEC 60079 typical suggests that the optimum period between inspections need to not exceed three years. EEHA examinations will certainly also be conducted beyond RBI campaigns as part of arranged maintenance and tools overhauls or fixings. These assessments can be attributed toward the RBI example dimensions within the influenced Great deals. EEHA evaluations are conducted to recognize mistakes in electric devices. A weighted scoring system is essential, as a single tool might have multiple faults, each with differing levels of ignition risk. If the mixed score of both inspections is less than twice the fault score, the Great deal is considered acceptable. If the Great deal is still considered undesirable, it should go through a full evaluation or reason, which might cause stricter assessment protocols. Accepted Whole lot: The causes of any faults are recognized. If a typical failure setting is located, additional tools might need maintenance. Mistakes are classified by intensity( Security, Honesty, Home cleaning ), ensuring that urgent issues are assessed and addressed quickly to alleviate any type of influence on safety and security or operations. The EEHA database ought to track and tape-record the lifecycle of faults together with the restorative activities taken. Implementing a durable Risk-Based Evaluation( RBI )technique is vital for making certain conformity and security in managing Electric Tools in Hazardous Locations( EEHA). Automated Fault Rating and Lifecycle Monitoring: Easily take care of faults and track their lifecycle to enhance examination precision. The intro of this support for risk-based assessment better strengthens Inspectivity's position as a best-in-class service for governing compliance, along with for any asset-centric assessment usage case. If you have an interest in finding out more, we invite you to ask for a presentation and discover just how our service can change your EEHA monitoring procedures.

With over ten years of mixed Ex-spouse experience (IECEx/ATEX, EEHA), Saipex began to promote the value of proficiency of all personnel associated with the Hazardous Location field in 2019. In 2021, our collaboration with IndEx and Technology Ability International (TSI) noted a milestone in the Saipex roadway to continue Ex renovation.

How Roar Solutions can Save You Time, Stress, and Money.

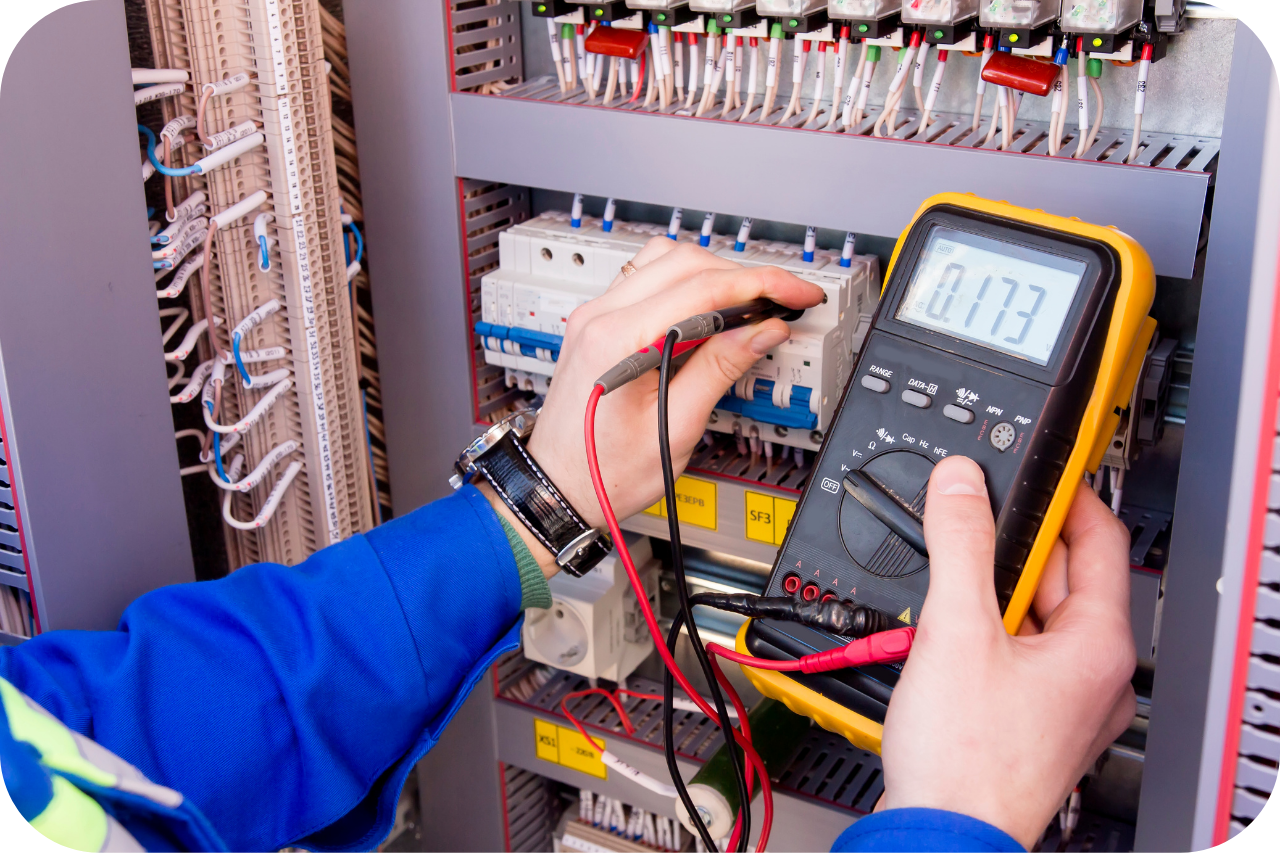

In regards to explosive risk, a harmful area is an atmosphere in which an eruptive environment is present (or might be expected to be existing) in amounts that require unique precautions for the building, installment and usage of tools. In this article we check out the challenges dealt with in the workplace, the risk control measures, and the called for competencies to function securely.

(https://www.bark.com/en/au/company/roar-solutions/Bz3O1R/)

These substances can, in particular problems, develop explosive environments and these can have major and awful effects. Most of us are familiar with the fire triangle get rid of any one of the three components and the fire can not take place, but what does this mean in the context of harmful locations?

This is then validated via assessment and screening and is protected throughout the life of the installment by employing the proper maintenance strategies, supplemented by routine inspection. When all these procedures are taken, they must likewise be documented. The verification dossier consists of info such as the harmful location classification drawing, manufacturers' documents, devices qualification, style illustrations and calculations, assessment records, and records of an individual's proficiency and continuing professional advancement (CPD), such as using ECA's eCOMS software.

Get This Report about Roar Solutions

It is critical that students comprehend and have a comprehensive expertise as to just what comprises a hazardous area. The pupil ought to additionally understand why training is essential prior to attempting to tackle work or defining devices into a hazardous area. These areas are also referred to as identified areas and are defined as areas which have a high likelihood of a surge as a result of the feasible existence of combustible gases, vapors, dusts etc.

Industries which contain hazardous areas are currently requiring that electric workers that are defining or functioning in these locations should have a hazardous area qualification that deems them competent. Jobs in these sectors are really satisfying so you need to be prepared. To fulfill this need for the industry, country wide recognised training in Certification IV in Dangerous area Electrical and EEHA training on the development of proficient specialists.

Excitement About Roar Solutions

Technology Skills Australia is a Registered Training Organization supplying you with one of the most affordable and quickest method acquiring your qualification - hazardous area electrical course. Our trainers are sector qualified and have a number of years of process experience. Our training courses have assisted numerous people from company supervisors to everyday workers in getting a strong hold on this not so challenging yet high risk training

The training also consists of recognizing the hazardous locations, sources of surge and the properties of unsafe products in addition to the obligations and features of all parties, guidelines, systems, criteria and practice codes attached to dangerous areas. We offer instrumentation and hazardous location solutions that are in compliance to most current AS/NZS and worldwide industry standards.

Report this page